Starting Line

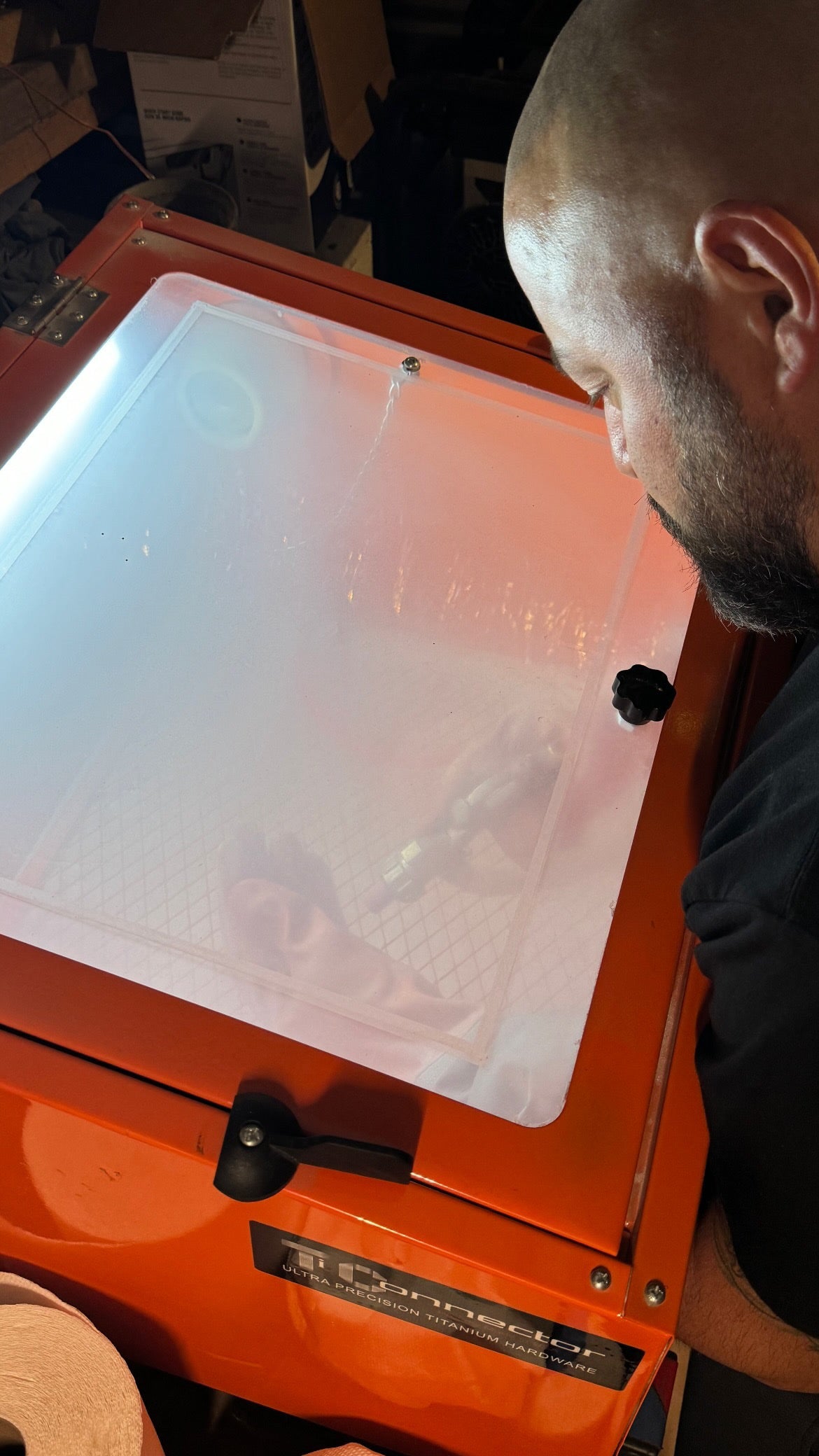

The 6al-4v titanium frames, pocket clips and CPM Magnacut stainless bladesteel all arrive in their raw form, having the profiles and pilot holes water-jet cut, ready for machining.

Blade Work

Each blade is surface ground for flatness, manually machined, the bevels rough ground to 120 grit and finally, sand blasted. After being professionally heat treated, the blades are then bead blasted and once again, ground by hand to a 220 grit full height gorgeous, belt satin finish.

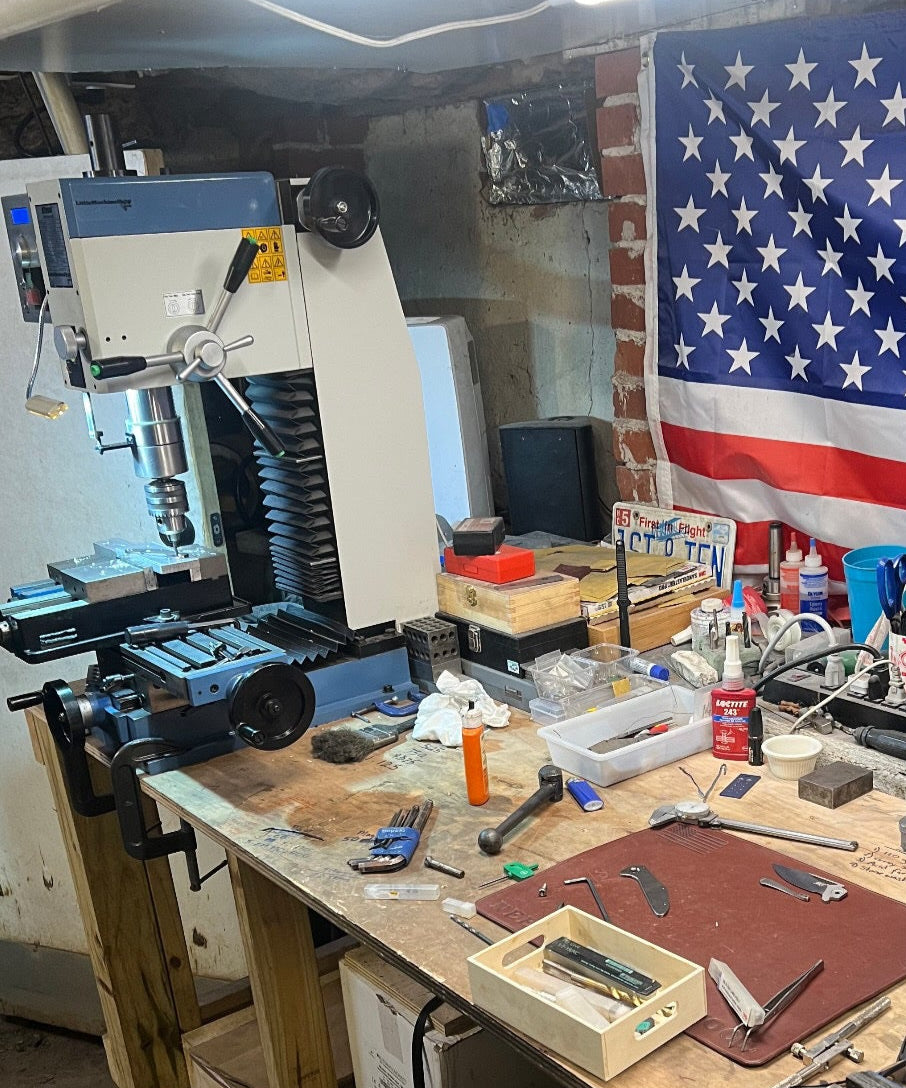

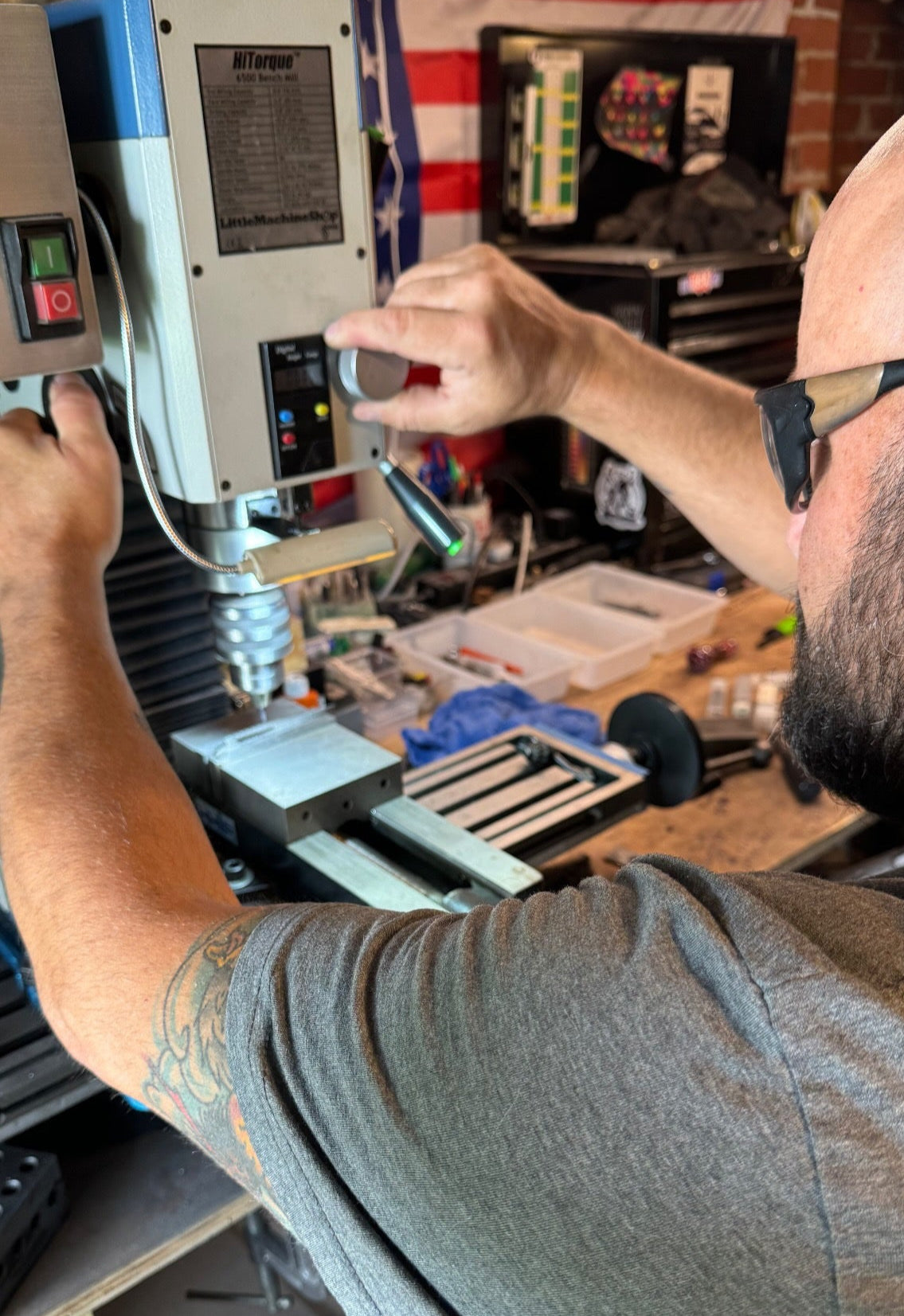

Frame & Pocketclip

All of the titanium frame scale features are manually machined with precision and tight tolerances. Then the profiles, flats and chamfers are ground by hand prior to being bead blasted to a smooth, satin finish.